Lean Sigma Consulting

Lean Enterprise

Even the most attentive businesses have the potential to strengthen their business strategy. We take a pragmatic, execution-oriented approach toward strategy development that delivers results. After all, setting the strategy is not the difficult part, the difficultly lies in how you execute your strategy and turn it into ‘Business As Usual’.

Transform & Grow the Business

What are your business goals? Does your strategy guide how you allocate resources? Can every employee articulate your strategy and are they empowered to execute on it? At UP Consulting, we see Lean Sigma as a Growth Strategy with equal emphasis on Quality and Flow that will amplify each other and accelerate the benefits.

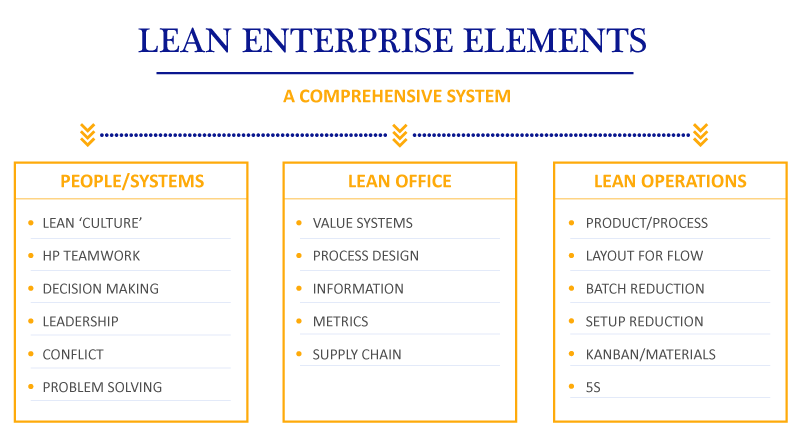

We draw on the synergies between Lean and Six Sigma methodologies to create a comprehensive and flexible system for achieving, sustaining and maximizing business success. We use only the tools that make the most sense for each situation to focus on the process optimization that will quickly make the biggest differences, ensuring faster results with a smaller initial investment.

What can Lean Consulting do for a business?

Achieve Operations Excellence

The key to a high performing process is to understand the current performance and maturity of a process, identify the level of performance required and establishing a path for achieving the desired output.

Improved Customer Satisfaction

By focusing on the customer and stripping away non-value added activities, precious capital is more precisely deployed improving sales, gross margins, and cash flow.

Enable & Sustain Change

To have sustainable business practices new habits need to be naturally assimilated into the businesses’ culture.

What are the techniques

used in Lean Sigma Consulting?

Effective process review and root cause analysis techniques will help your business focus on lucrative opportunities for process improvement.

Lean

Seeks to optimize the flow of products and services throughout the value stream to maximize customer value and minimize waste with fewer resources.

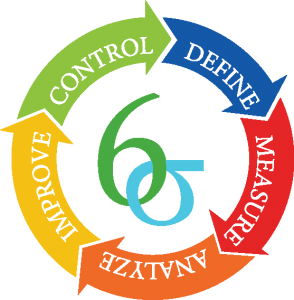

Six Sigma

Seeks to improve the quality output of process by identifying and removing the causes of defects (errors) and minimizing variability in manufacturing and business processes.

Quality First

Develop both an organizational mindset and mistake proof processes to eliminate quality defects.